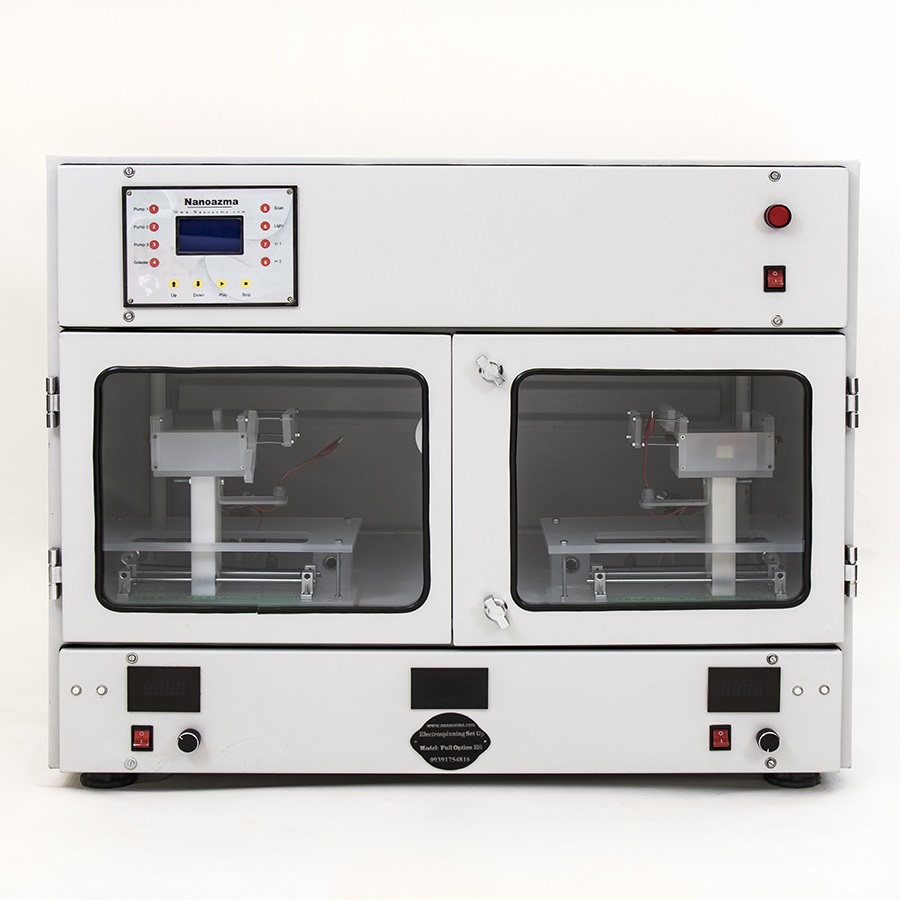

Electrospinning Unit

Electrospinning method makes use of an applied voltage to form very fine fibers (typically on micro or nano scale) from a liquid. Electrospinning shares characteristics of both electrospraying and conventional solution dry spinning of fibers. The process does not require the use of coagulation chemistry or high temperatures to produce solid threads from solution. This makes the process particularly suited to the production of fibers using large and complex molecules.

Applications

- Nanofiber production with specific porosity, shape, diameter, thickness, orientation, etc.

- Nanofiber production employing all synthetic, natural, biodegradable polymers and/or polymer/composites

Special Features

- Exceptional ease of use

- Versatile production of normal, ceramic, hybrid nanofibres; as well as hollow, two-component, composite fibers derived from one, two or three independent polymers simultaneously

- Laboratory scale for research purposes

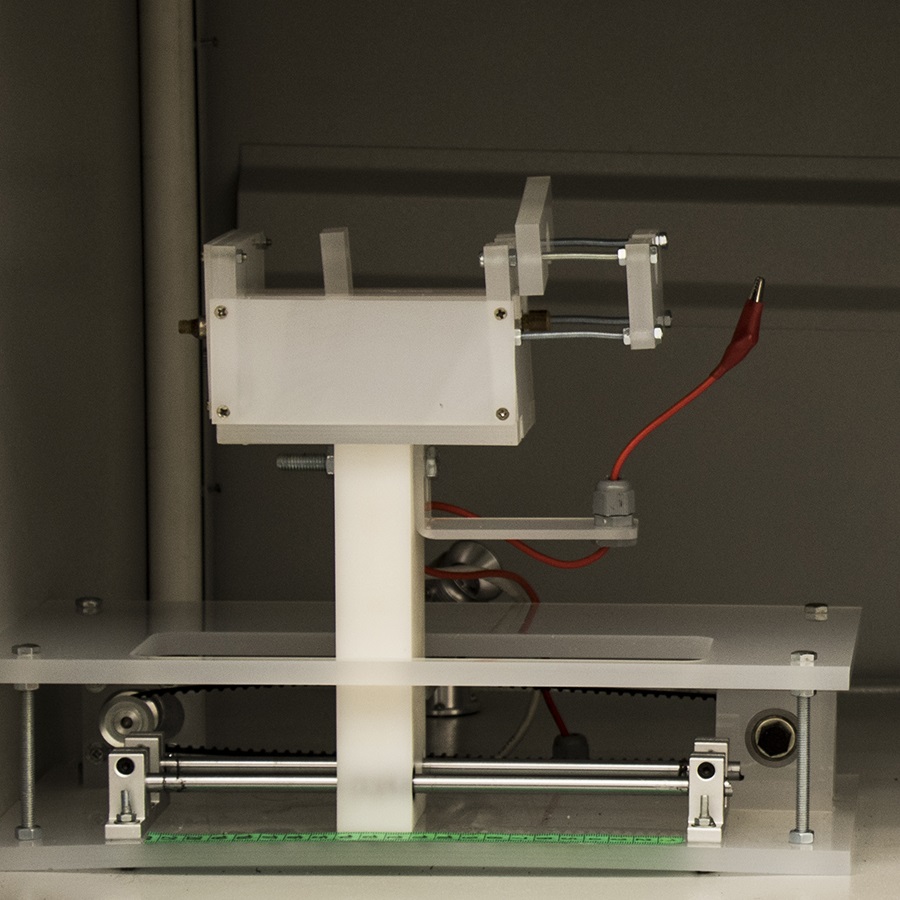

- Various collectors (wire, disk, cylinder and plane)

- Digital control with large display and 20 switches

- Automatic movement in X-Y directions

Technical Specifications

- Electrospinning distance: 5-20 cm

- Injection precision: 0.1-10 ml/h

- Number of nozzles: 3

- Number of pumps: 3

- Drum speed: 0-3000 rpm (controllable)

- 2 High voltage power supplies: up to 25 kV

- Safety system for high voltage